The System

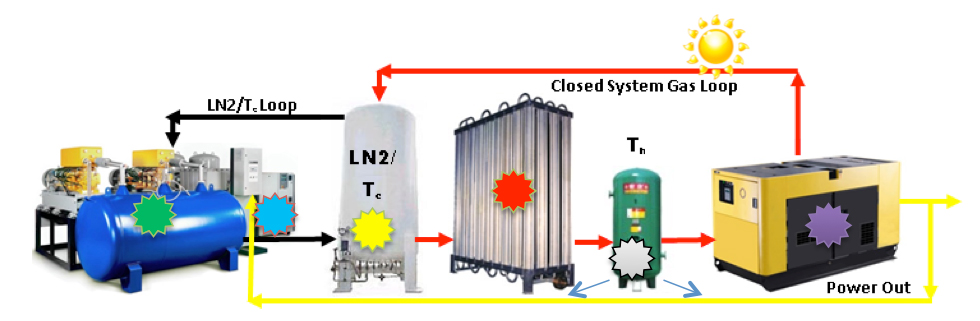

The LN2G Power Generation Plant incorporates a variety of trusted commercial components working together as an assembly utilizing proven methodologies and the characteristics of LN2 in a more efficient manner to produce energy. Simply put as part of the LN2G plant assembly we are replacing the steam and the turbine with a proprietary drive mechanism and flywheel while utilizing standard off the shelf components to complete the power plant to generate sustainable, predictable, usable and consistent power, 24 hours a day 7 days a week.

The LN2G Power Generation Plant is a System that has multiple components that fit within the framework of the statements below.

Primary Plant Components

There are 6 primary elements of the LN2G system.

![]() LN2 Production (facilitated by a commercial Cryo Production PSA system)

LN2 Production (facilitated by a commercial Cryo Production PSA system)

![]() Water Chiller/Re-circulation Unit (with storage capacity depending on system size)

Water Chiller/Re-circulation Unit (with storage capacity depending on system size)

![]()

Cryo-Liquid Storage (Commercial Liquid Storage Tank(s)

![]()

Heat exchange/Vaporization (HTF/Molten Sodium storage plus Proprietary vaporizer)

![]()

Commercial Generator (with proprietary Compressed Gas Drive)

![]()

Proprietary Gas Recirculation “plumbing”

The compressed (pressurized) Nitrogen Gas expansion process produces the energy to power the Generator. When Liquid Nitrogen, which is about -365°F is allowed (or caused) to rise in temperature, via the Passive Solar Thermal Energy that heats the air, the Liquid Nitrogen quickly changes into a gas (at a rate of about 900 to 1), and if it’s in a container, creates pressure. That pressurized gas puts the flywheel (replaces the turbine) into motion to run the generator to produce the electricity. LN2G is the result of 10 years of development and more than 7 years of practical testing and validation.

The LN2G Power Generation Plant by definition is comprised of multiple components and processes that make up the entire System. A Diesel Generator is within itself, a type of system technically, but not considered from an industrial application to be a “System”, but rather one component within a larger Plant comprising many components.

Technical / Operational / Costing and Revenue Points:

- Complete Plant Space Requirements – .08 Acres /MW

- Grid Interface – All SCADA, Controls, and Transfer Switches (where required)

- Input Energy – One or some combination of the following: This is a zero cost of operations feature and one that is exclusive to the LN2G electric power generating resource operating 24/7/365 days a year.

- a. Ambient temperature/Solar Thermal (stored heat energy in the atmosphere)

- b. Scavenged heat from within the system in combination with ambient

- c. Waste heat energy from an industrial or other resource in close proximity. (i.e. a furnace, boiler, manufacturing process, etc.)

- Maximum system output requirements to produce LN2 (Liquid Nitrogen) relative to system size is 8% respectively of system output (will be less on smaller systems such as 300kW, 500kW). The Declared Sellable/usable electric power will be no less than 85% of the total system value in kW or MW (meaning the income or saving derived from the use of an LN2G system is calculated on whatever the specific rate structure is multiplied by the minimum system output value over a 24 hour period).

Typical Site Integrated Plant Layout and Configuration Examples:

Shopping Center, Industrial, Commercial

Shopping Center

Download a PDF of AIP Shopping Center Plan

Industrial

Distribution and Warehousing